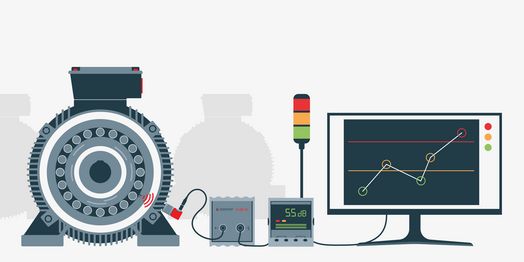

Preventive Maintenance with Ultrasound

In most factories, regular preventive maintenance is performed to reduce machine failures, increase plant availability and to save energy costs. With the multi-purpose ultrasonic testing devices of the SONAPHONE family, many of these tasks can be carried out quickly and efficiently. The operation is simple and extensive trainings are no longer needed.

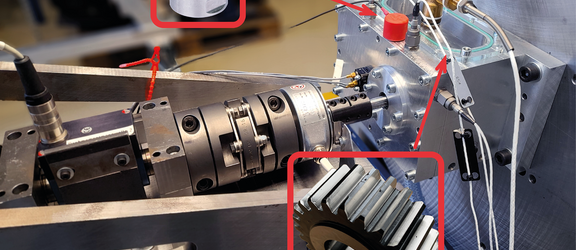

The SONAPHONE devices detect leakages in compressed air, gas and vacuum systems. They reliably inspect bearings, the functioning of valves as well as steam traps and detect electrical partial discharges on medium or high-voltage equipment. By applying an ultrasonic transmitter the SONAPHONE devices can also be used for tightness testing of cabins, hatch covers, containers and other unpressurized systems.

Do you have any questions?

Feel free to contact us! We will be happy to help you.