Optimizing CHO Processes in Bioreactors

Maximize Product Yields by Implementing Non-Contact Flow Meters and Air Bubble Detectors

Flow meters play an important role in various steps in biopharmaceutical manufacturing to ensure process stability and efficiency. High accuracy flow meters and air bubble sensors can help maximize product yields, improve product quality, and achieve the goals of the PAT framework.

Get more details about our featured products:

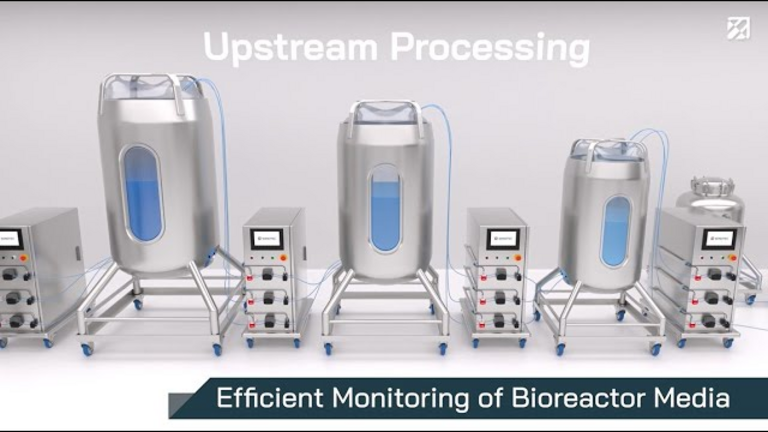

Enhancing Upstream Bioprocessing

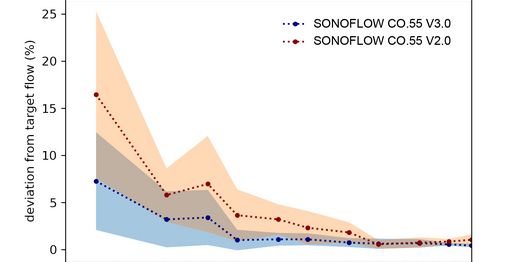

The supply of nutrients and the removal of by-products to and from the cell culture affect cell density and viability, the duration of the bioprocess and, as a result, product titer, yield and cost. Therefore, optimizing nutrient feeding is critical throughout the bioprocess - for batch, fed-batch, continuous and perfusion culture. Perfusion describes a process where the cells are kept in a bioreactor while the culture medium is continuously replaced. Fresh medium replenishes nutrients, while cellular waste and nutrient-depleted medium are removed. Highly accurate flow meters can efficiently monitor the volume flow to and from of the bioreactor and thus ensure the specified product quality.

Considering upstream operations such as supplying substrate for cell culture feeding, maintaining optimal growth conditions in fermentation, or cell separation and product isolation in harvesting, the implementation of high accuracy ultrasonic flow meters offers a number of advantages for the upstream process.

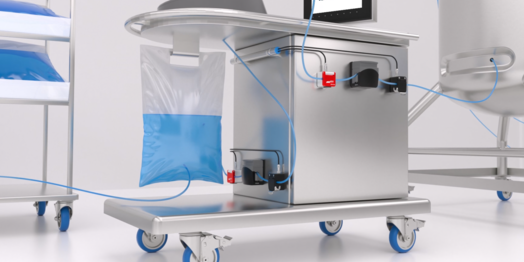

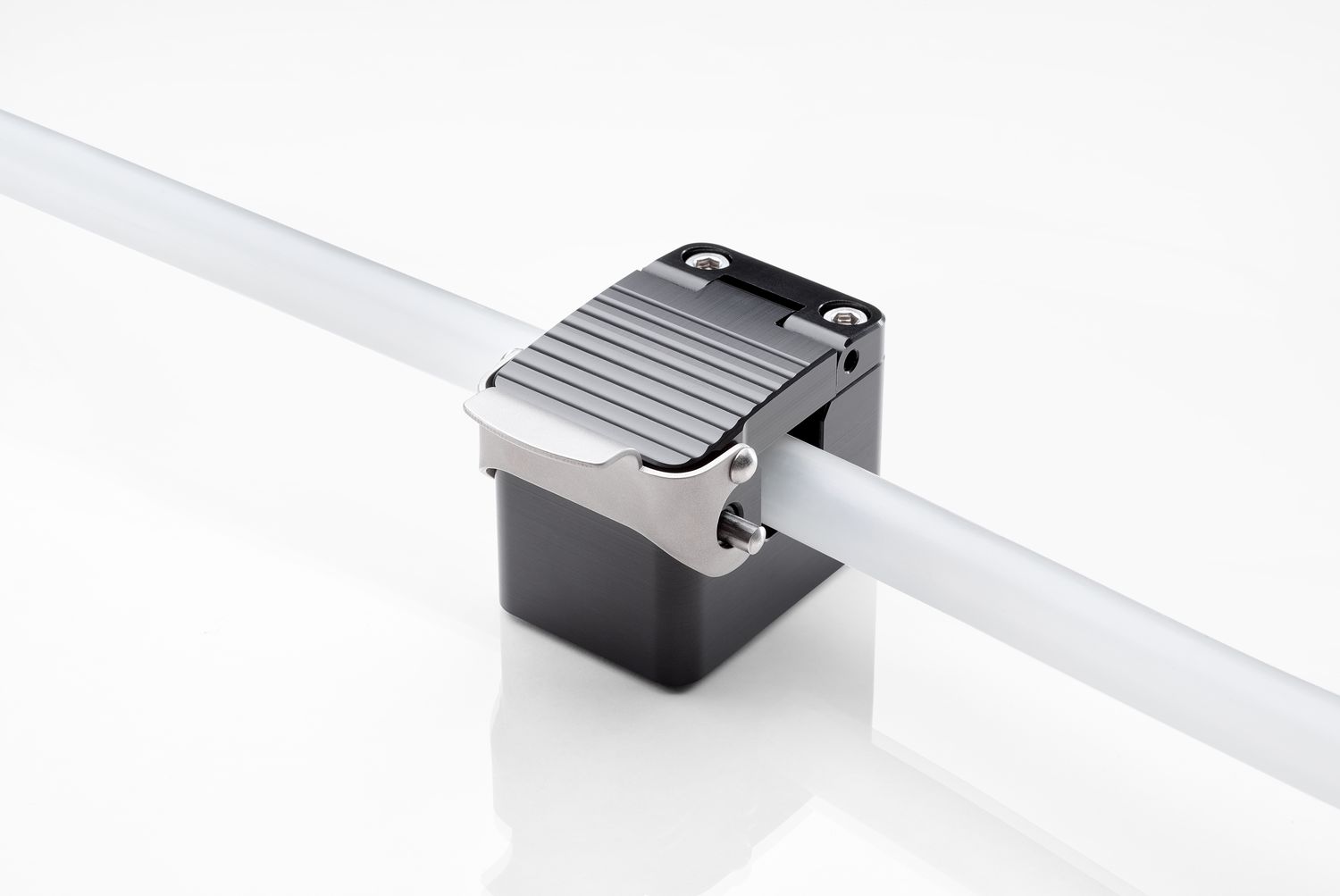

Non-contact clamp-on flow meters can be used to automatically measure and dispense culture media – time- and volume-controlled. Thus, flow meters are a cost-efficient and convenient alternative for laboratory balances. Real-time data acquisition of critical process parameters allows seamless monitoring of the bioreactor media, allowing automatic adjustments of the feeding rate at any time.

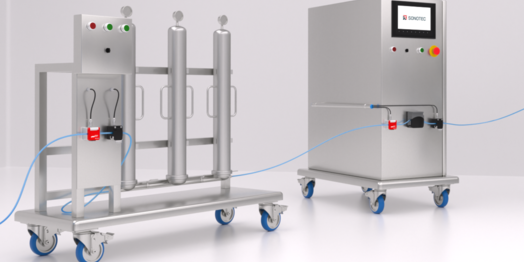

Process Safety with Air Bubble Detection

Using clamp-on air bubble detectors can increase process stability and safety. These sensors detect enclosed air in the tubing system early on, ensuring that the volume of liquid fed in is not reduced due to air.

In addition, air bubble detectors can also be used to monitor the fill level in order to prevent the medium from running dry and, if necessary, to avert pump damage.

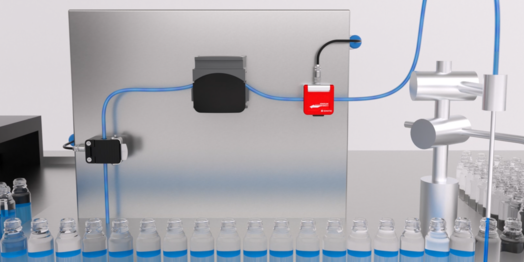

Real-Time Flow Measurement and Air Bubble Detection

Non-contact clamp-on flow meters enable precise control and optimization of process parameters at all stages of the upstream bioprocess, resulting in improved efficiency and product quality.

Real-time flow measurement and air bubble detection are performed continuously during the process, enabling constant parameter monitoring to enhance accuracy and efficiency.

Why are flow meters and air bubble detectors important for CHO upstream bioprocessing?

- Improving automation and control through accurate flow and volume measurement data

- Increasing material and energy efficiency through optimized process control to achieve sustainability goals

- Encouraging continuous processing, leading to time, space and cost savings

- Contamination-free measurement thanks to non-invasive ultrasonic measurement technology

- Implementation of Pharma 4.0 concepts and AI models thanks to various sensor data, fast response times, and modern interfaces

- Compact sensor design with stainless steel housing that combines space-saving installation and resistance to aggressive cleaning agents

Benefit from our flow meters and air bubble detectors!

More Information about Ultrasonic Flow Meters

Do you have any questions?

Feel free to contact us! We will be happy to help you.