Higher Accuracy and Efficiency in Filtration

Monitoring the Performance of Filters with High Accuracy Flow Meters and Air Bubble Detectors

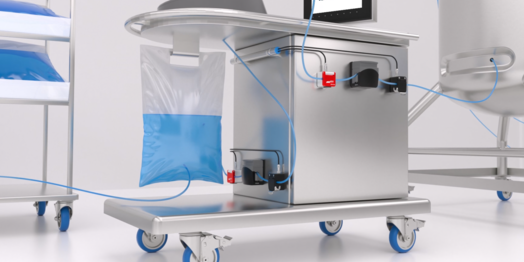

In the manufacturing process of biopharmaceuticals, filtration is essential for purification and separation to obtain product purity. Optimizing flow rate and volume ensures efficient processing for high product quality. Non-contact clamp-on flow meters enable real-time monitoring without direct contact with the medium and without interrupting operation.

Get more details about our featured products:

Improving the Filtration Performance

Filtration is a critical step in the purification of biopharmaceuticals such as proteins, antibodies, and vaccines. It describes the separation of undesired particles from biological materials by using different types of purification technologies such as alternating tangential flow filtration (ATF), tangential flow filtration (TFF), or ultrafiltration (UF) to obtain contamination-free products.

The performance characteristics of the filter, including flow rate and capacity, play an important role in the filtration process. It is important to optimize the flow rate to ensure efficient processing without affecting filtration performance. Non-contact clamp-on flow meters can be used for both real-time flow rate control and volume control to ensure consistent filtration performance.

For consistently high performance, filters must be cleaned regularly and wetted before use. Proper cleaning removes residual contaminants, while effective wetting ensures optimal filter performance and consistent flow rates.

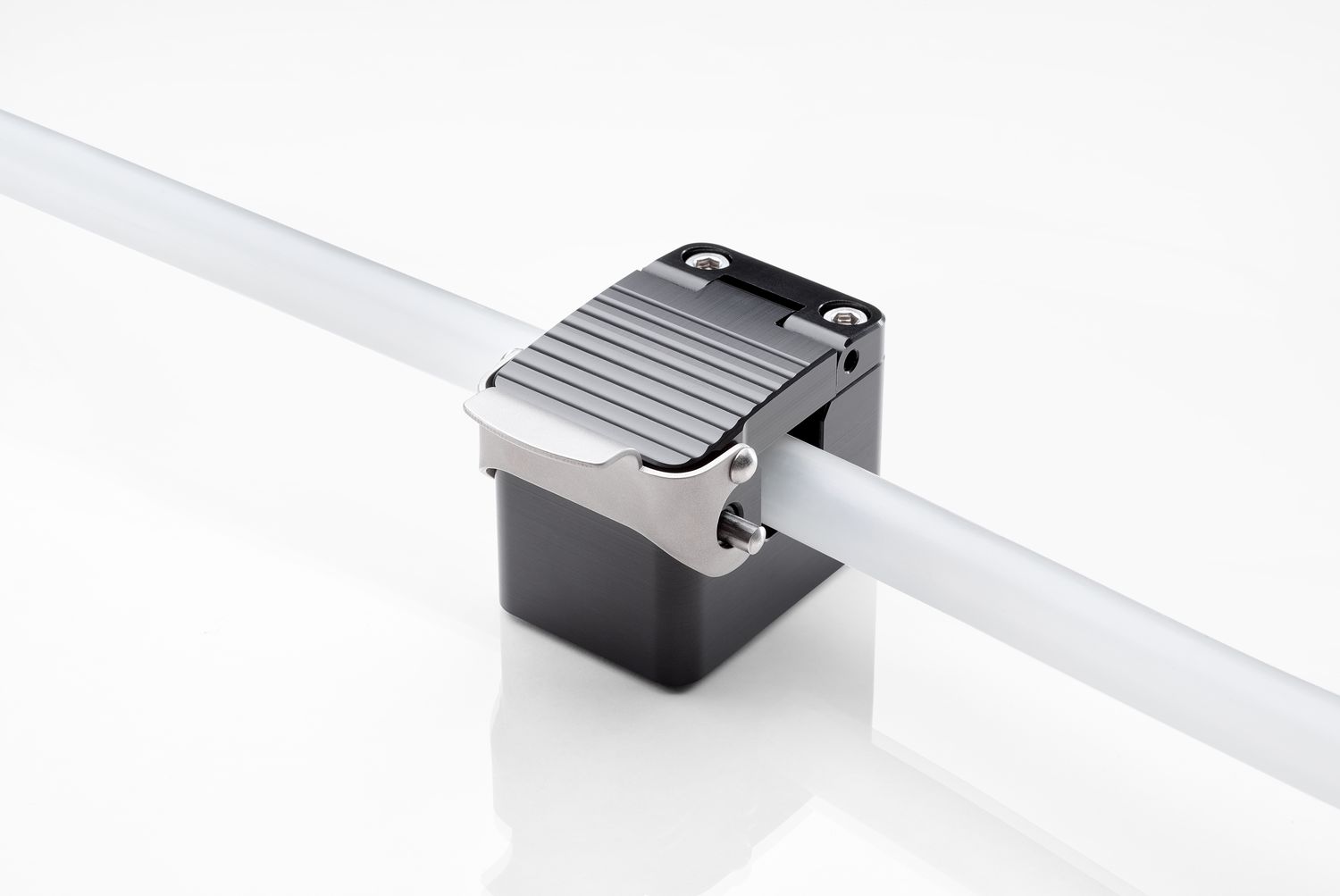

Non-contact ultrasonic flow meters enable accurate, real-time flow monitoring without disrupting sterile environments or requiring system downtime. Their non-invasive clamp-on design minimizes contamination risk and maintenance requirements, supporting more reliable and efficient filtration operations.

Enhanced Filter Protection

The presence of air bubbles can have a significant impact on the efficiency of the filtration cassettes and therefore negatively affect product quality and yield. Early detection of air bubbles prevents uneven pressure distribution, ensuring consistent and reliable flow and filtration performance.

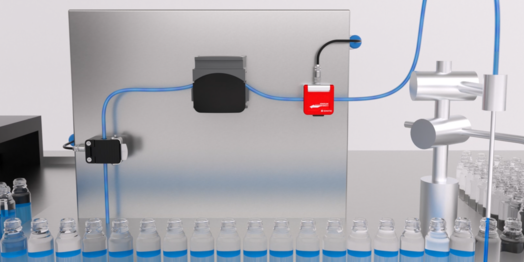

The SONOCHECK ABD06 ultrasonic air bubble detectors reliably detect air bubbles without having contact with the medium. Thanks to the transmission principle, the sensors measure through the wall of the tubing. They are free of wear and tear.

Real-Time Flow Measurement and Air Bubble Detection

Filtration is important in the purification of biopharmaceuticals, including proteins, antibodies, and vaccines. Optimizing the flow rate and capacity is essential for efficient processing without compromising performance.

Non-contact clamp-on flow meters enable real-time monitoring without disrupting the process. The early detection of air bubbles is crucial to prevent pressure imbalances, ensuring reliable filtration.

Why are flow meters and air bubble detectors important for filtration & purification?

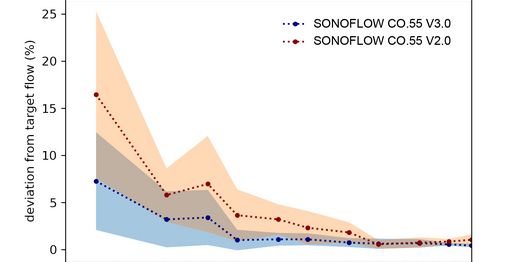

- Enhanced Accuracy and Repeatability:

Non-contact flow meters provide real-time flow rate measurements with an accuracy of 1%, ensuring consistent filtration performance to meet high PAT requirements. - Automation & Process Control:

Various sensor performance data can be used in AI models to analyse filter conditions or flow anomalies. - Constant High Product Quality:

Ultrasonic air bubble detectors signal the presence of air bubbles, preventing sudden pressure drops in the process and potential harm to product quality. - Minimizing Downtime:

Clamp-on flow meters can be installed quickly without disrupting the process. These sensors are cost-efficient and free of wear and tear.

Benefit from our flow meters and air bubble detectors!

More Information about Ultrasonic Flow Meters

Do you have any questions?

Feel free to contact us! We will be happy to help you.