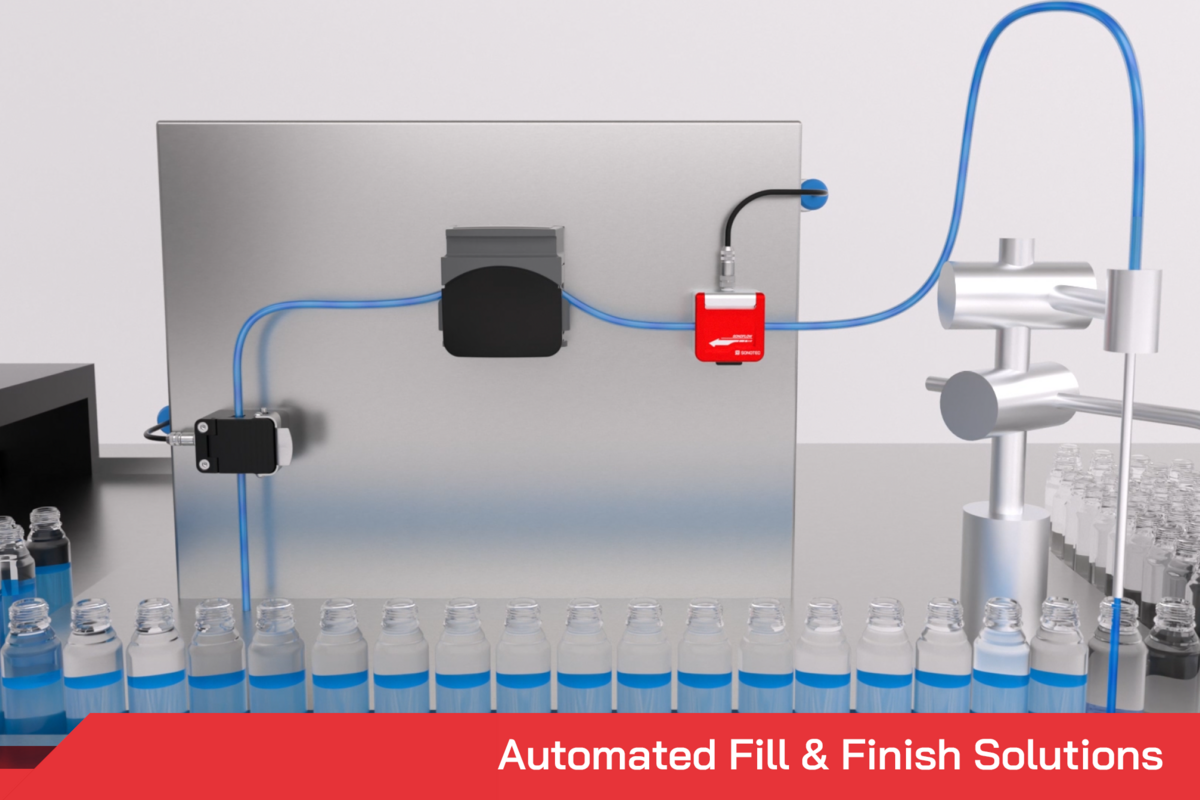

Enabling Automated Fill & Finish Solutions

Achieving Batch Consistency by Implementing High Accuracy Non-Contact Flow Meters and Air Bubble Detectors

In biopharmaceutical production, the fill & finish process is a critical stage where both accuracy and sterility have a direct impact on product quality and patient safety. Achieving high accuracy in flow measurement and ensuring air-free filling are essential to maintaining batch consistency, process quality, and reducing waste.

Get more details about our featured products:

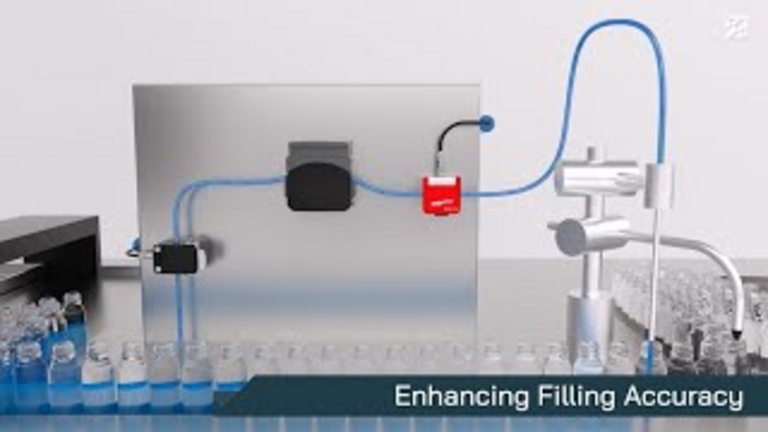

Enhancing Filling Accuracy

Precise flow measurement ensures that each vial, syringe, bag, or container has the correct product volume. Even small deviations can lead to underfilling, which reduces the effectiveness of the medication for the patient, or overfilling, which results in costly product loss. Non-contact ultrasonic flow meters are used to monitor the flow rates and the volume of liquids in real-time and with high accuracy.

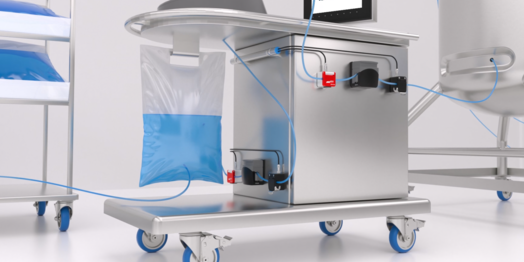

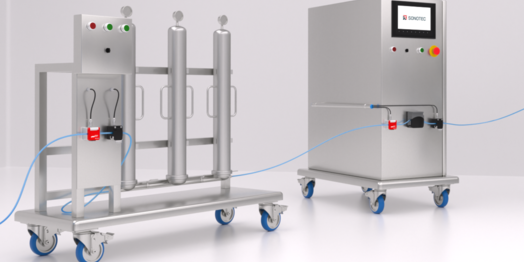

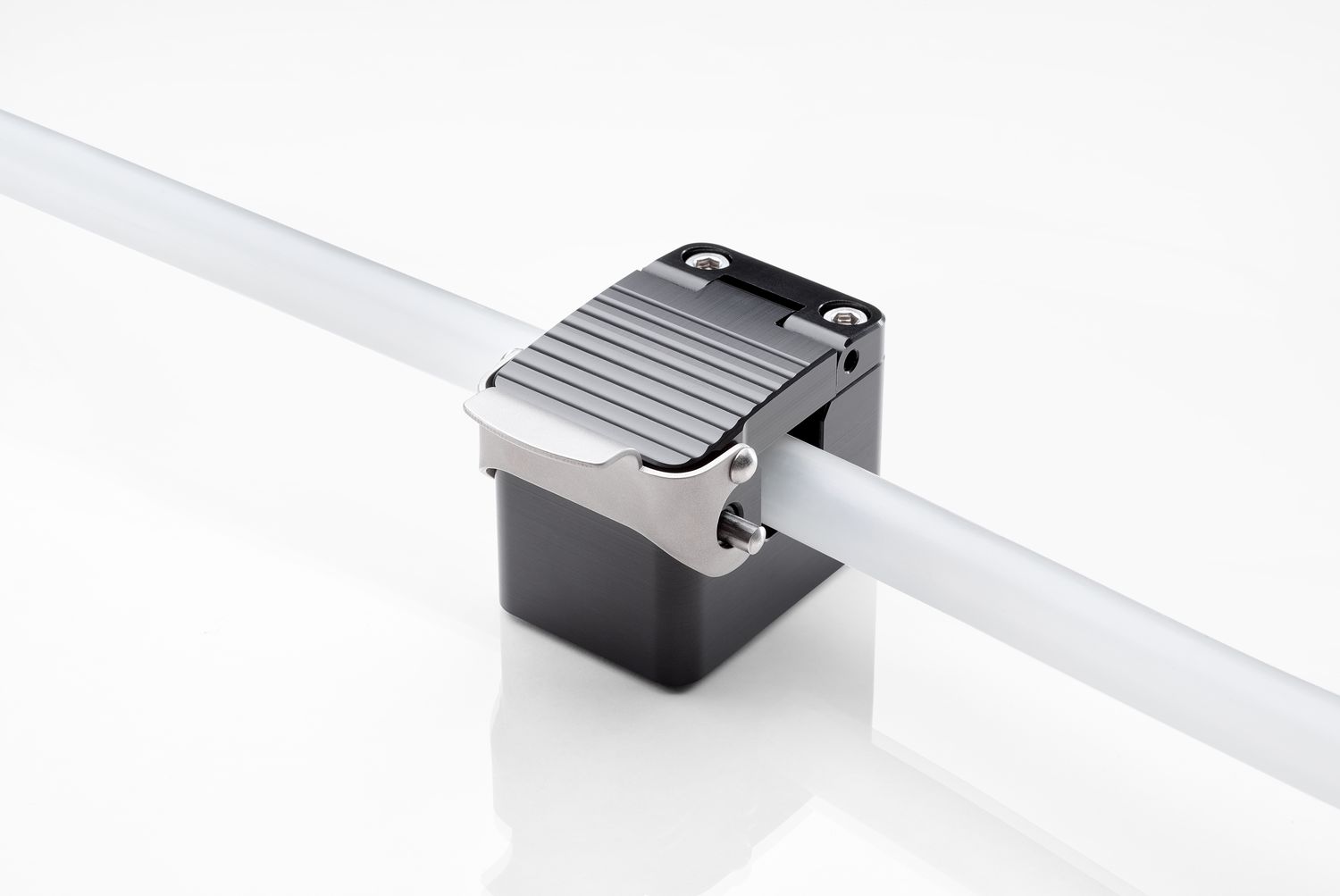

Fill and finish processes must be highly flexible and scalable, from aseptic filling in a laboratory setting of 1 mL to commercial production of 1,000 L. Therefore, the implemented measurement devices must also be scalable. SONOFLOW CO.55 flow meters are available in several sizes to fit different tubing sizes. The sensors are easily clamped on the tubing and measure without any contact and therefore without any risk of contamination or leakage.

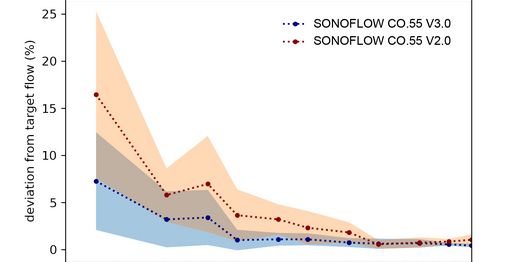

Designed with a special focus on low flow applications, the SONOFLOW CO.55 V3.0 clamp-on flow meters offer excellent measurement accuracy across a broad flow range and the highest level of clamp-to-clamp repeatability. The non-contact sensor is perfectly suited for single-use environments with regular tubing replacements. With the smallest footprint in the market, the compact and reliable flow meter with built-in electronics can easily be integrated in fill & finish solutions.

The presence of air bubbles in the fill & finish process can affect product quality and lead to dosing inconsistencies. Effective air bubble detection systems are crucial for a smooth, contamination-free process. By implementing air bubble detectors of the SONOCHECK ABD06 series, airless filling of biopharmaceuticals can be guaranteed. The non-contact clamp-on SONOCHECK ABD06 sensor detects air bubbles via ultrasound in the tubing.

The implementation of non-contact flow measurement and air bubble detection sensors can significantly improve the fill & finish process to enable automated filling solutions. This can considerably reduce product and material loss, human error and the risk of contamination, while increasing process flexibility.

Real-Time Flow Measurement and Air Bubble Detection

Non-contact flow meters and air bubble detectors are essential for the accurate, hygienic and efficient dosing and filling of biopharmaceuticals, which is essential for the safety and efficacy of the medication.

Why are flow meters and air bubble detectors important for fill & finish processes?

- High Accuracy:

Filling accuracy up to ± 1 mL with small volumes - Contamination-Free Non-Invasive Measurement:

Enhanced process safety and efficiency - Real-Time Monitoring:

Ensuring immediate correction of deviations - Automation & Control:

Various sensor performance data for AI models used in process monitoring

Benefit from our flow meters and air bubble detectors!

More Information about Ultrasonic Flow Meters

Do you have any questions?

Feel free to contact us! We will be happy to help you.