Non-Contact Flow Meters & Bubble Detectors

For Biotechnology

Designed for upstream and downstream monitoring of bioprocesses, the non-contact ultrasonic sensors from SONOTEC measure liquid flow quickly and accurately. With their integrated electronics board, the SONOFLOW and SONOCHECK sensors offer the smallest equipment footprint solution on the market. Additionally, we offer different options for sensor calibration.

Get More Information About Flow & Bubble Sensors in Bioprocessing

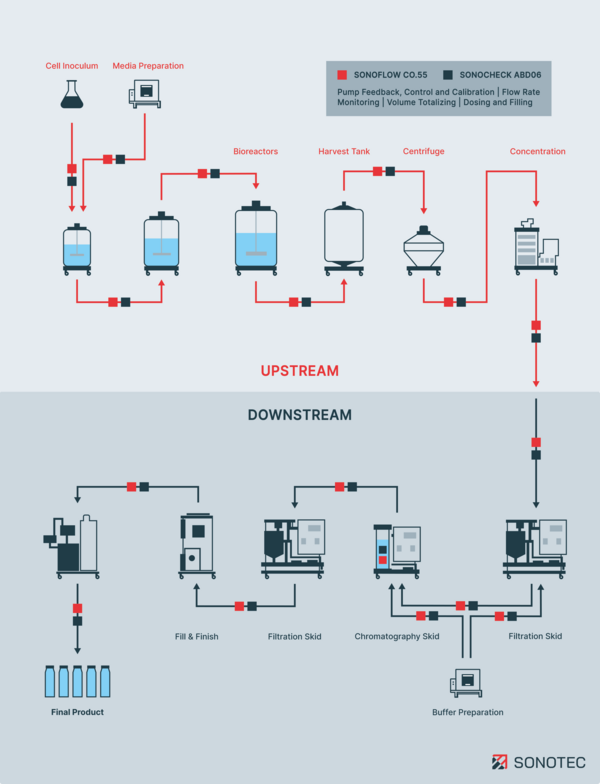

Applications of SONOFLOW® & SONOCHECK® Sensors in Bioprocesses

Applications of non-contact flow meters SONOFLOW CO.55 and bubble detectors SONOCHECK ABD06 in upstream and downstream processes of the bioprocessing industry:

- Pump feedback, control and calibration

- Flow rate monitoring

- Volume totalizing

- Dosing and filling

Video: Sensors in Bioprocessing

Implementing SONOFLOW CO.55 non-contact clamp-on flow meters and SONOCHECK ABD06 ultrasonic air bubble detectors at various steps in upstream and downstream bioprocessing.

More Application Areas of Non-Contact Flow Meters & Bubble Detectors

Do you have any questions?

Feel free to contact us! We will be happy to help you.