SONOAIR® R&D

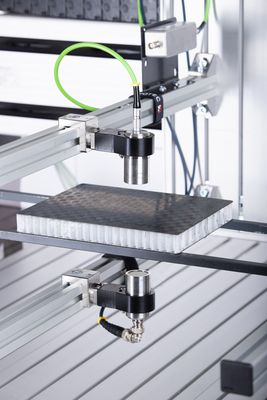

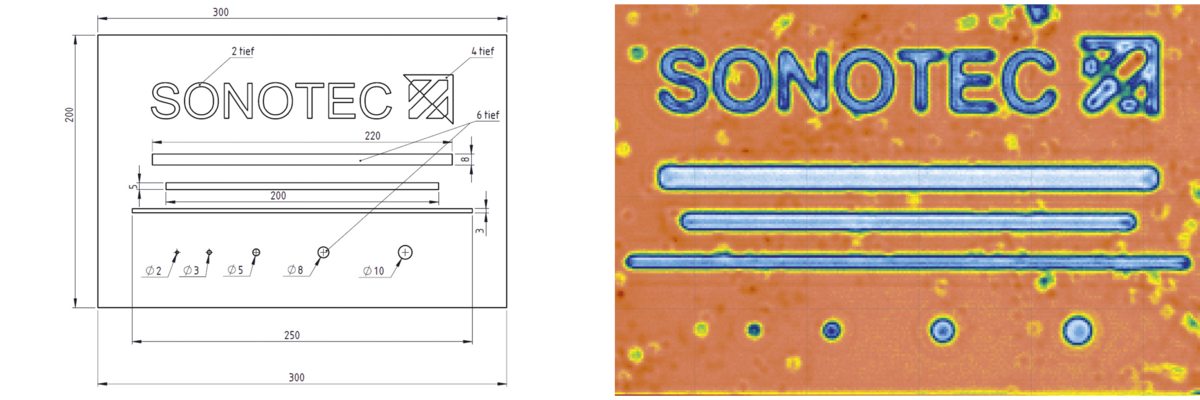

Non-Contact Ultrasonic Laboratory Testing System

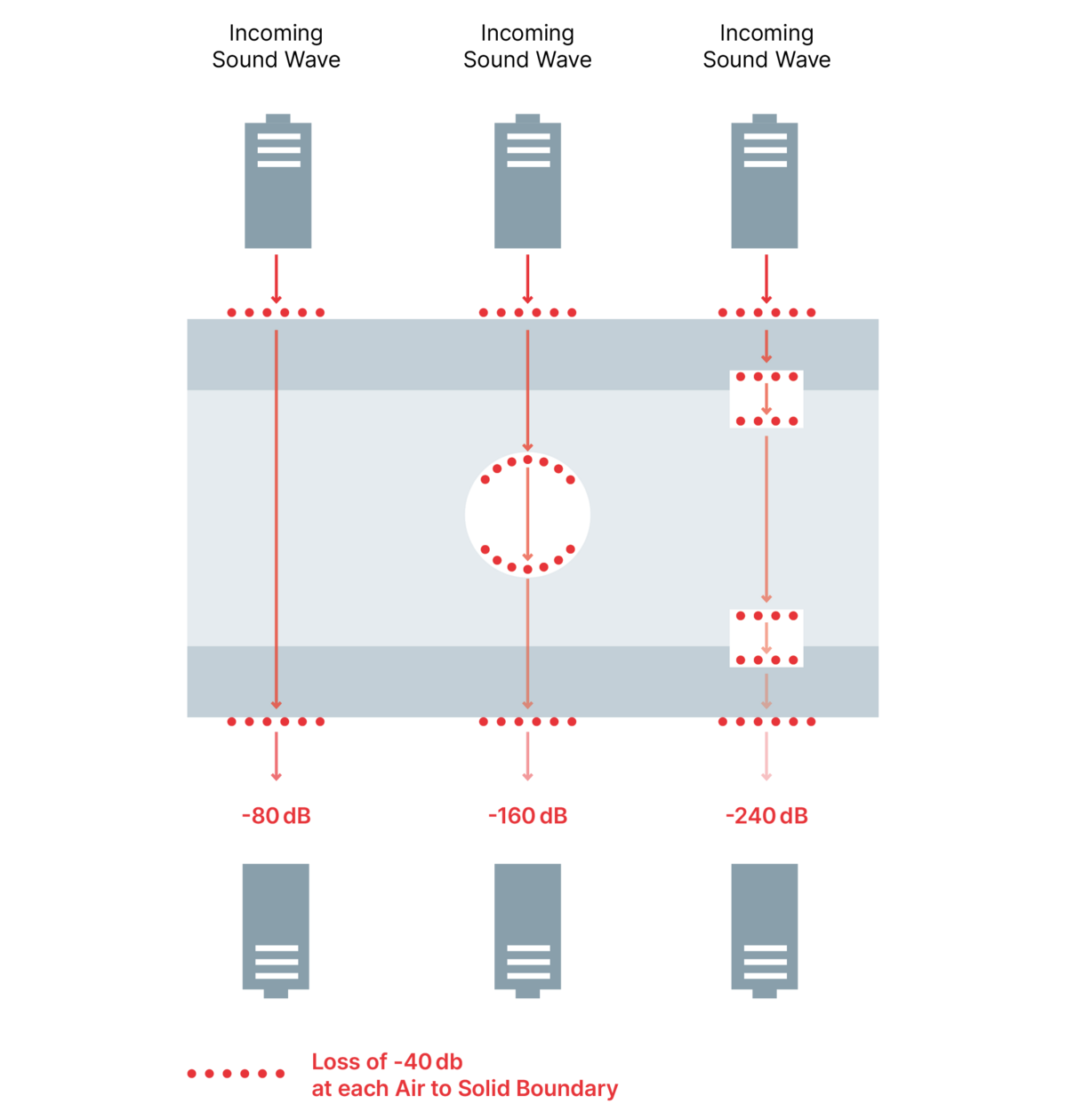

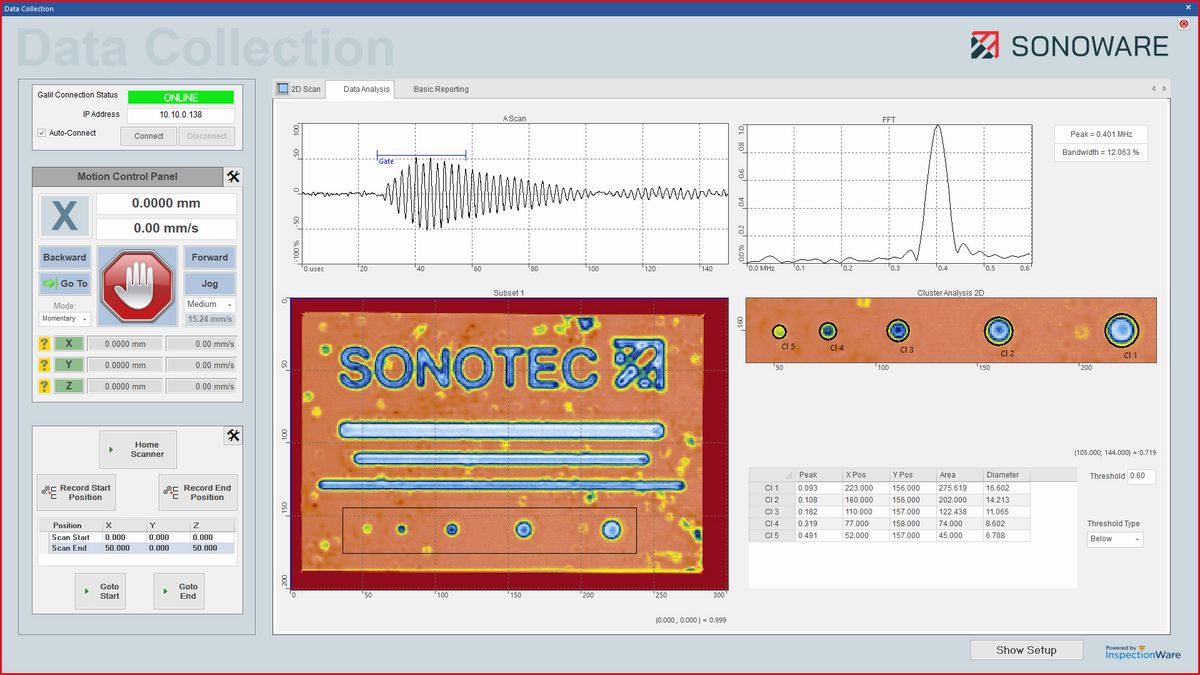

SONOAIR R&D features a free configuration of the sender characteristics with a pulser voltage of up to 800 V. Through a combination of a pre-amplifier on the receiver (probe integrated or external) and a post-amplifier inside the electronics the system generates an ultra-low noise level of less than 1nV/√Hz. The receiver dynamic of 120 dB provides an industry leading signal to noise ratio (SNR) even with highly attenuating materials and leads to clear and reproduceable measurement results.

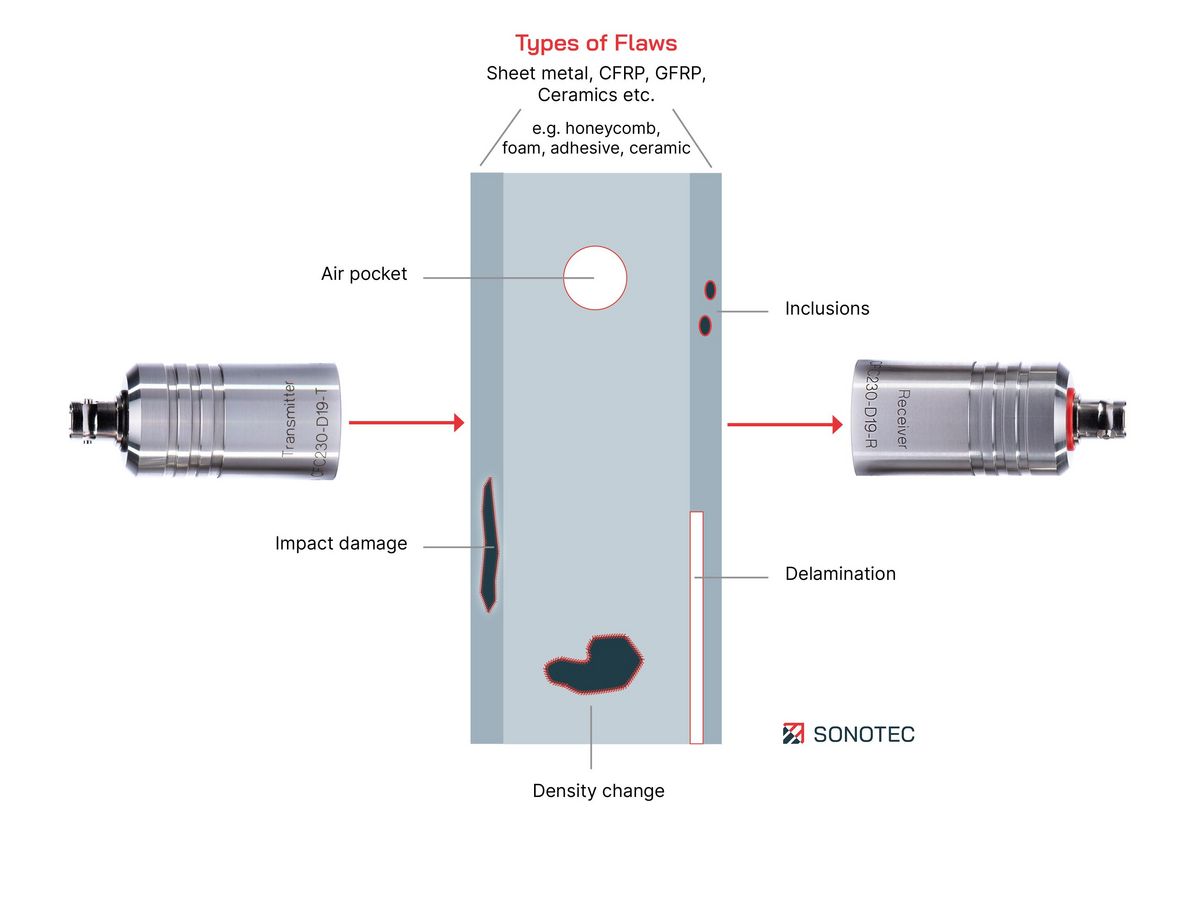

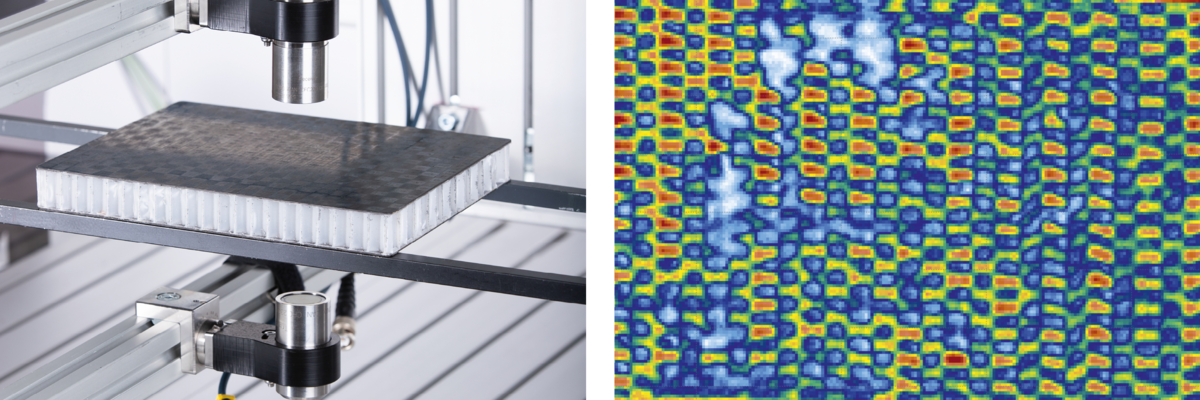

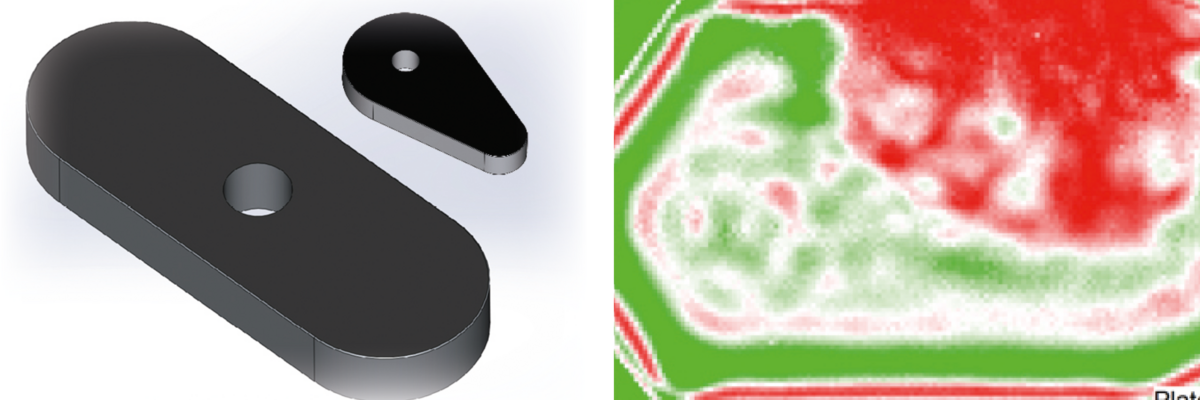

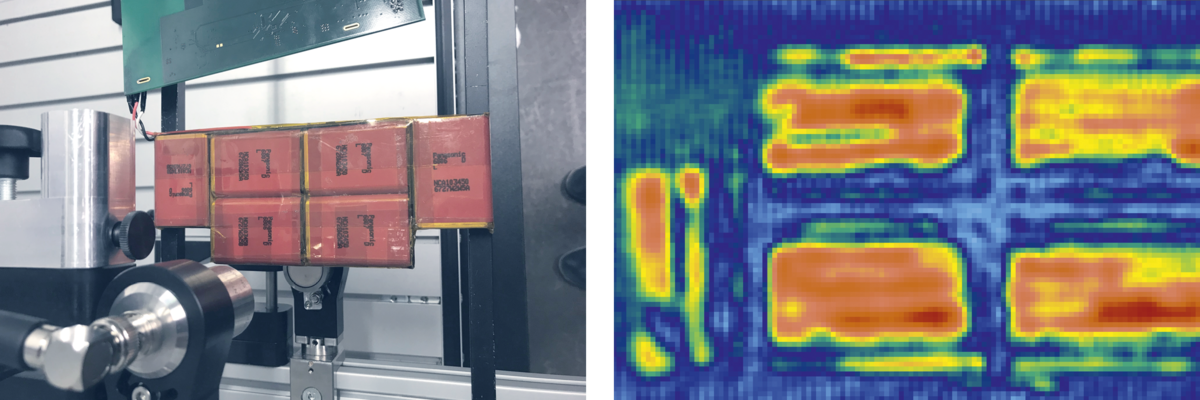

Applications

More about our NDT Products

Do you have any questions?

Feel free to contact us! We will be happy to help you.