Steam Trap Testing

Reduce Energy Costs and Increase Process Stability with Ultrasonic Testing Devices

The regular inspection of valves and steam traps is essential for preventive maintenance. The early detection of steam trap leaks or fails and signs of wear leads to increased operational reliability, and considerable cost savings.

Advantages at a Glance

- Reduce energy costs by up to 20 %

- Increase process stability

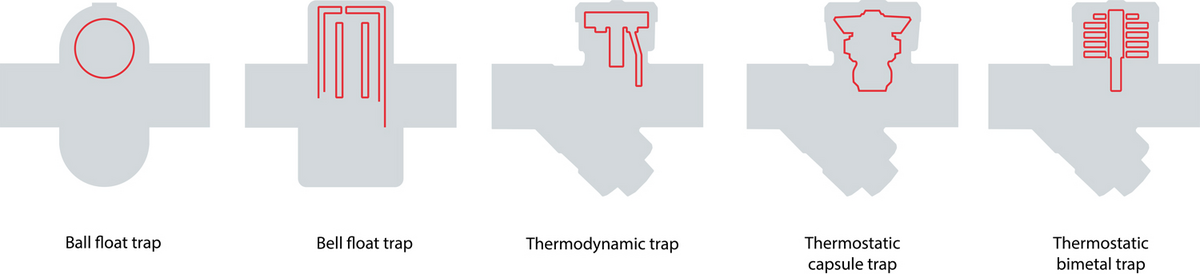

- Check all types and brands quickly and inexpensively

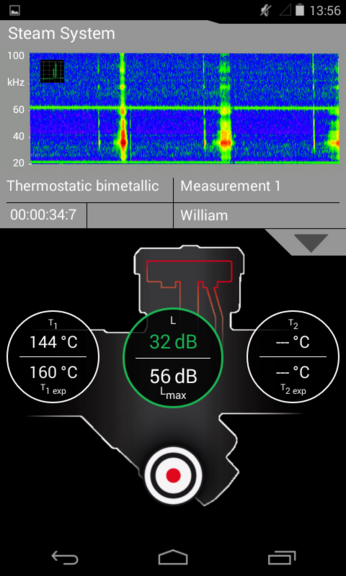

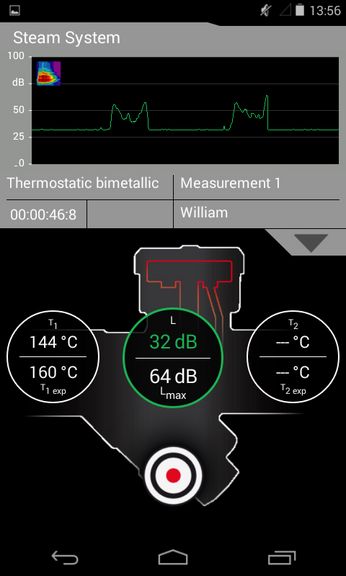

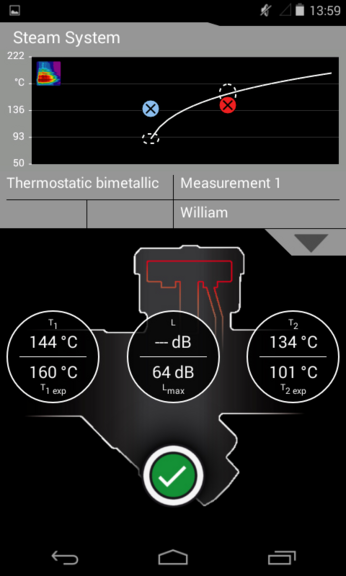

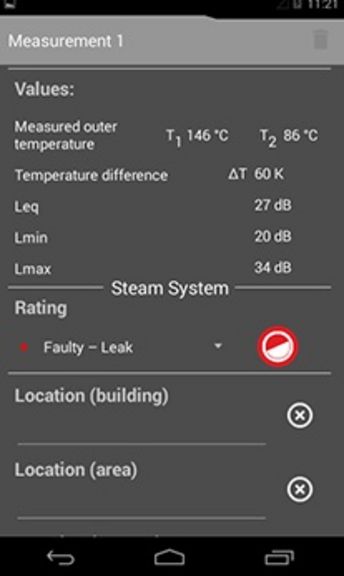

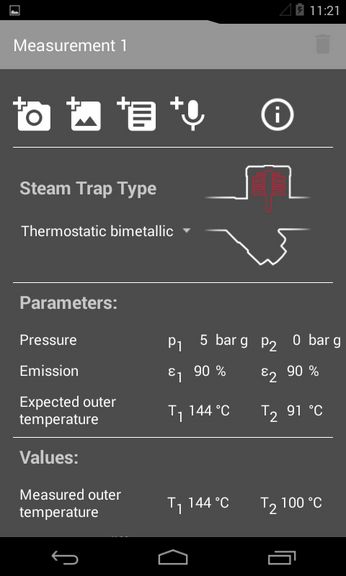

- SteamExpert App for steam trap testing for SONAPHONE

- SteamExpert Software module for SONAPHONE DataSuite

- Reporting and Trending

mySONAPHONE

Products

Do you have any questions?

Feel free to contact us! We will be happy to help you.