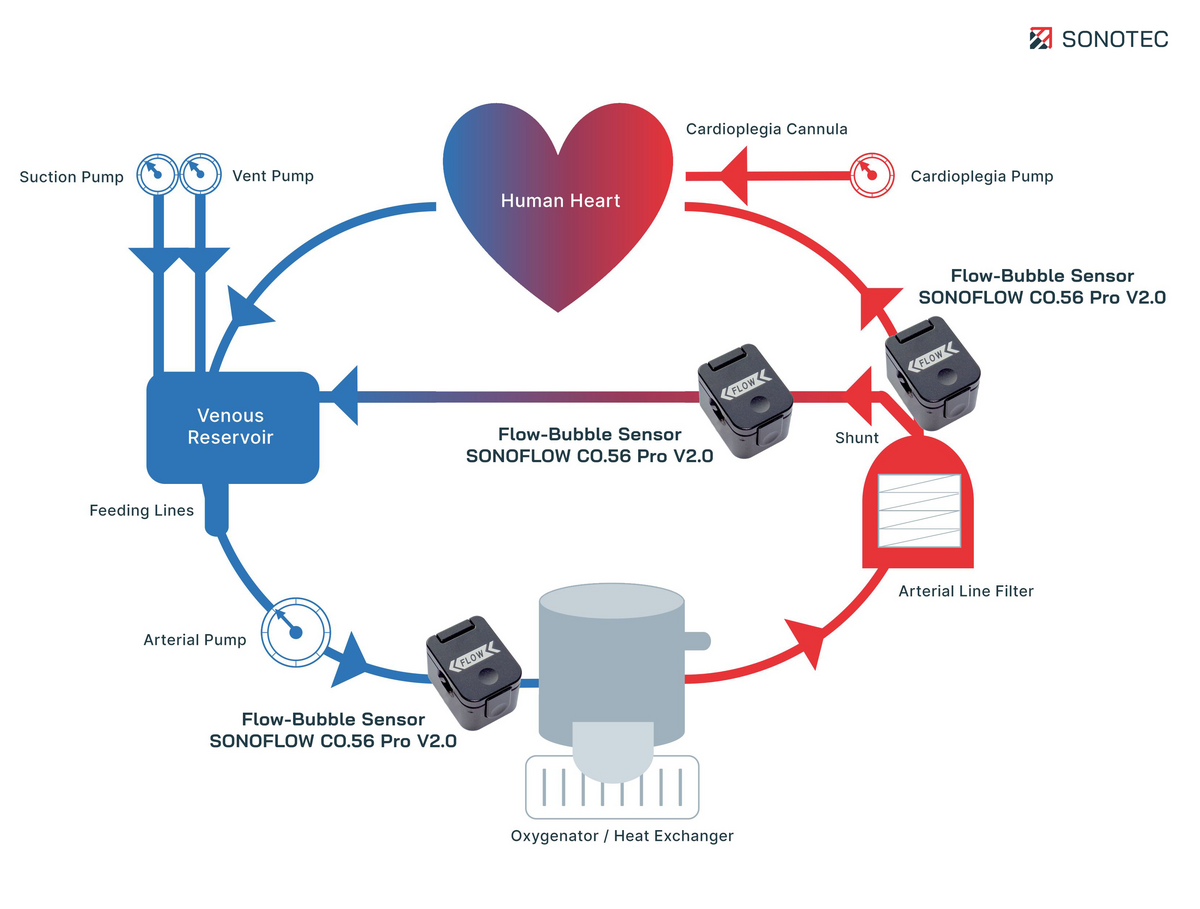

Flow-Bubble Sensors For Heart-Lung Machines

Hybrid SONOFLOW® CO.56 Pro Sensors Designed Into Cardiopulmonary Bypass Pumps

Cardiopulmonary bypass (CPB) is a method that temporarily takes over the function of the heart and lungs during surgery, maintaining the human blood and oxygen circulation. The CPB pump, often also named as heart-lung machine (HLM), deals with human lives. Hence, technical requirements are specifically high. A reliable operation of all utilized equipment must be guaranteed at all times. For that reason, combining flow measurement and air bubble detection constitutes a significant safety and comfort feature.

Benefit from Our Flow-Bubble Sensors

More Information about Ultrasonic Flow Meters

Do you have any questions?

Feel free to contact us! We will be happy to help you.