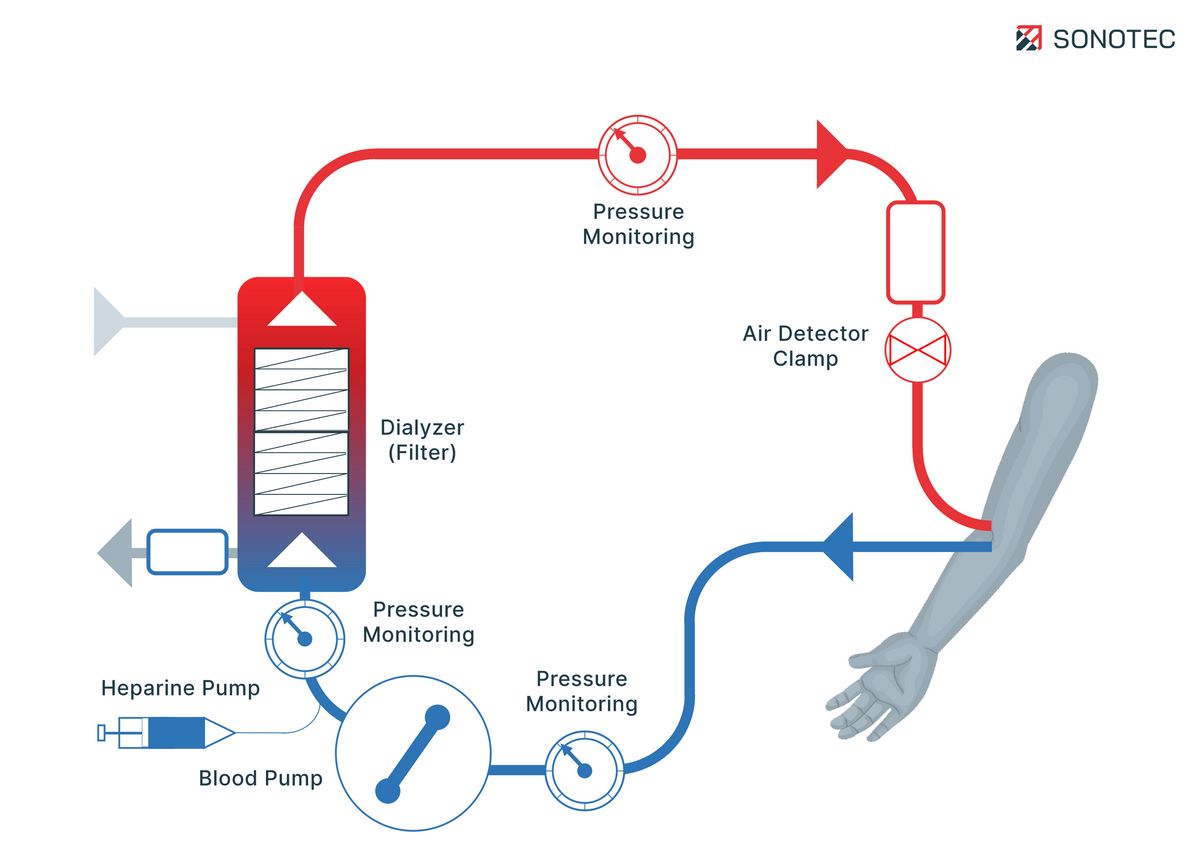

Air Bubble and Blood Leak Detection in Dialysis Machines

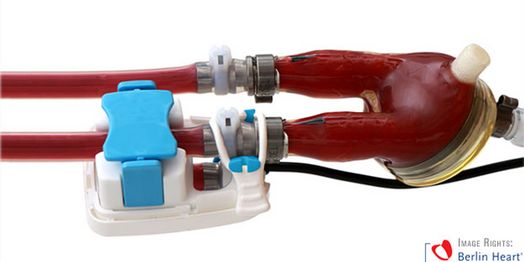

Hemodialysis is an essential and routine medical treatment for which safety has become a clinical priority. Therefore the process requires a chain of interventions to ensure maximum patient safety. Dialysis machines combine a variety of sensors for the monitoring of pressure, flow and liquid level as well as for detecting leaks and air in the tubing system.

Benefit from Our Air Bubble Sensors & Blood Leak Detectors

More Information about Non-Invasive Ultrasonic Sensors

Do you have any questions?

Feel free to contact us! We will be happy to help you.