Minimization of Systemic Measurement Errors

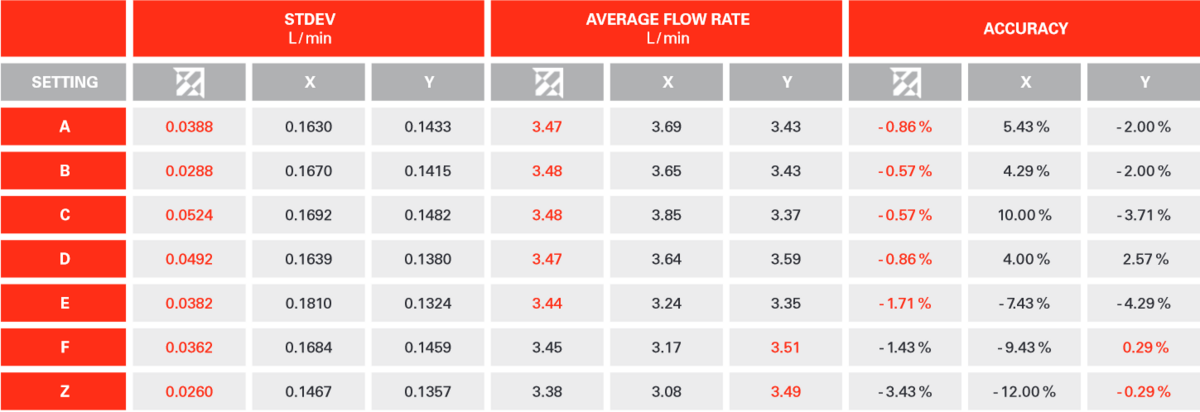

The sensor set-up was chosen to minimize systemic measurement errors while comparing the sensors to each other. All test conditions were kept as stable as possible by using the same sensor and application set-up in steady ambient conditions such as temperature and air pressure. All sensors have been calibrated to the applied test setup to finally refer to the pump output at 3.5 litres per minute.

As the precision specifies the repeatability of the sensor describing how consistent results could be reached; accuracy in turn, defines the error between the real and the measured value.

Accuracy, indeed, is finally an issue of a high precision and an optimum calibration of the sensor.

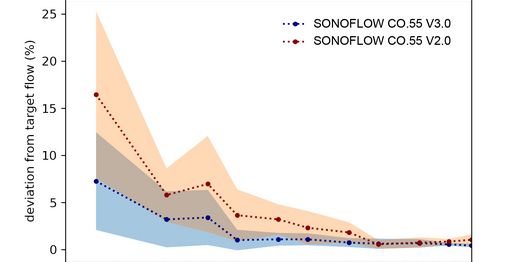

With reaching the best values of the standard deviation during each run, the SONOFLOW CO.55 V2.0 shows the best precision of all competing sensor set-ups. This outstanding performance makes sure to also reach consistently high accuracies, ranking the SONOFLOW CO.55 V2.0 top in five of seven of the simulations realized. This, however, could be even topped by an improved calibration to the test environment.

The high resolution of the SONOFLOW CO.55 V2.0 is therefore also one of the key reasons reaching these exceptional results.