Non-Contact Ultrasonic Testing

Laboratory Testing System for Air-Coupled Ultrasonic Inspections

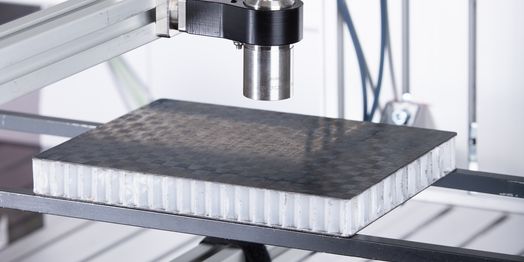

Our non-contact ultrasonic SONOAIR Technology enables measurements on highly attenuating materials that were hardly or not at all testable with water-coupled ultrasonic testing. This allows ultrasonic non-destructive testing of state-of-the-art fiber composites, such as GFRP and CFRP, or even highly damping honeycomb structures, which are used primarily in modern lightweight construction.

Non-Contact Ultrasonic Testing of Fibre Composites

In contrast to conventional testing, no liquid coupling and no direct contact with the test object is required. Air-coupled Ultrasound is not a new technology. It was primarily used in the aerospace industry in the 1970s. However, the possibilities of the technology at that time were very limited (error resolution, sensitivity, software post-processing, modularity, etc.) and were never really further developed.

With the advance of lightweight construction, renewable energies, additive manufacturing, etc., contact-free air-coupled UT is gaining in importance again. Many components cannot be wetted with liquid coupling due to material or production-dependent properties, such as liquid causing the material to swell, peel, corrode, or otherwise be destroyed. Existing systems with liquid coupling (e.g. squirter or immersion technology test systems) also require complicated water supply and drainage as well as lengthy and costly drying processes.

The SONOAIR Laboratory System enables measurements on highly attenuating materials that were hardly or not at all testable with Water-coupled Ultrasonic Testing. These include, among others:

- Composites (CFRP/GFRP)

- Honey comb structures

- Foams

- Ceramics

- Wood

- Concrete

In addition, ultra-modern fibre-plastic composites can be checked for defects of the same size be tested as with conventional Ultrasonic Testing Methods.

More about our NDT Products

Do you have any questions?

Feel free to contact us! We will be happy to help you.