1. Leak detection and quantification

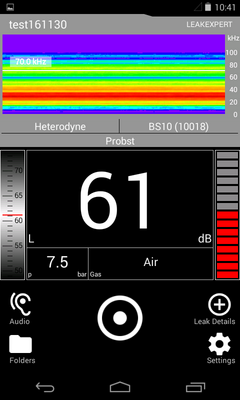

Leaks in compressed air, gas and vacuum systems lead to air flows that can be located using ultrasound. These signals are processed using the testing device and the airborne sound sensor, and leaks are made audible. With various attachments for small and large distances and the graphic display of spectrogram and level curve, you are optimally equipped for leak detection and evaluation.

- Broadband analysis of the ultrasound signal in a frequency range from 20 to 100 kHz

- Graphic display of spectrogram and level curve on the display

- Individually adjustable process for making signals audible (phase vocoder/heterodyne)

- Use of high-quality noise-protection headphones (noise-canceling)

- Evaluation of the leak at the touch of a button, and immediate display of the loss in liters per minute. Automatic classification of the leak size in order to estimate the savings potential

2. Documenting the leaks

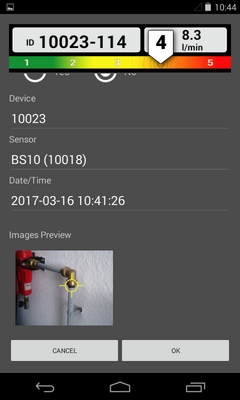

The LeakExpert® software guarantees simple and structured testing and documentation. Test paths can be defined by entering the building, area, system and component, and help to locate leaks quickly during repair work. You can also add additional information in the form of text comments and voice memos, and take photos with the integrated camera.

- Simple organization and management of the leaks thanks to the clear structure in the device

- Individual prioritization of the individual leaks

- Storage of detailed information on the repair and option to add voice memos

- Quick recording of photos with the integrated camera and marking of potential weak points with markers

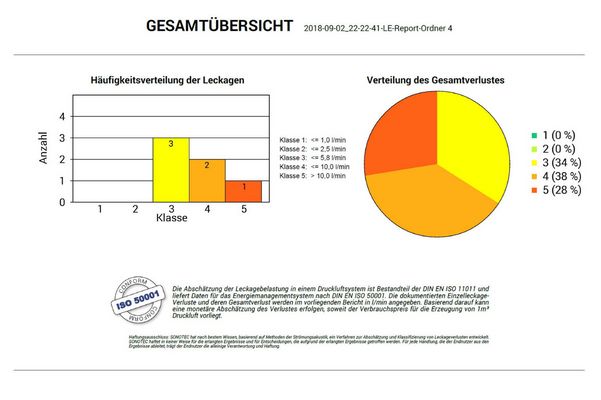

3. Evaluating the measured data

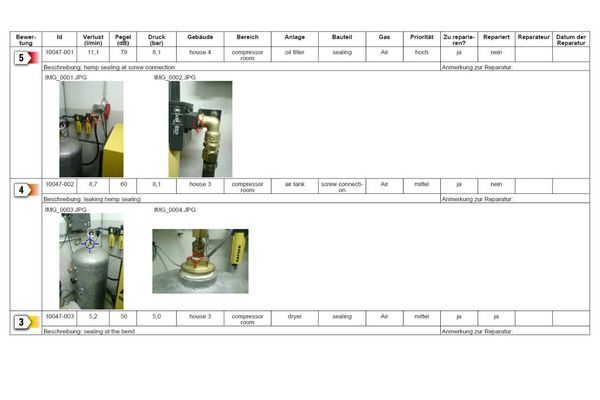

Save time not only when recording but also when evaluating your measured data. With just a few clicks, you can create a professional evaluation for management or your customers at the end of your testing procedure. The different export functions make it easy for your to integrate the measured data into existing maintenance software. A PDF report can also be created of your work, summarizing all of the data in a structured manner and showing it in the form of diagrams.

- Simple transmission of the test data to your maintenance software by exporting a CSV file (text file of the data for further processing)

- Clear summary of the testing procedure in a PDF report: Processing the measured data in diagrams with information relating to the total loss. Clear listing of all saved leaks including text comments, photos and repair information

- Option to create a ZIP file to backup all test data (including sound files and photos)