CBM + RELIABILITY CONNECT® Live Training Conference Europe 2023 will take place on 20-22 June - We take part!

Our application engineer Christian Probst will give a presentation on the advantages of broadband ultrasonic sensors for machine and rolling bearing testing on 22 June at 14:45.

With the new SONOTEC transducer principle, we enable measurement in the range of ultrasound over high-frequency structure-borne sound up to the acceleration range - and all with one sensor. In his presentation, Christian Probst will go into detail about the transducer principle, focusing on the technology and properties of piezocomposites and requirements for the calibration of the sensor type.

More on the topic

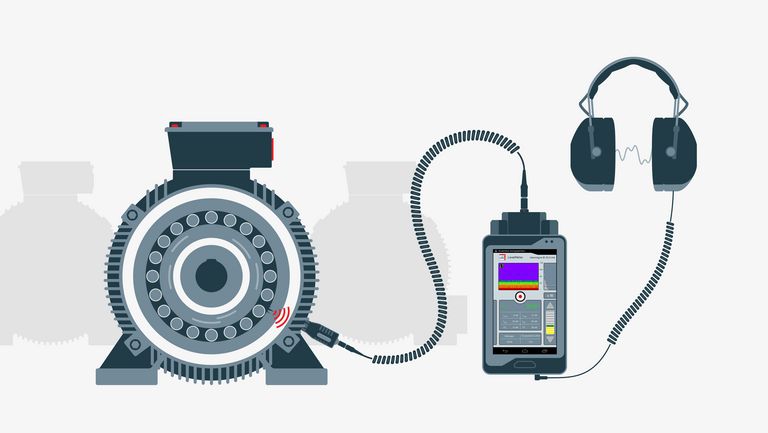

In the field of condition monitoring of rotating machinery or other equipment and processes, both vibration analysis and ultrasonic testing play a key role. While ultrasound is used as a technology for early failure detection in rolling bearings, vibration is normally applied for the overall machinery condition inspection and root cause analysis. In practice, both methods are often used simultaneously. Measurements are usually taken at the same measuring points on the asset.

SONOTEC´s new transducer principle enables measurement of the range from ultrasound to high frequency structure-borne sound and even down to the range of acceleration with one sensor. In the presentation, this transducer principle is explained in detail with the focus on the technology and the unique characteristics of piezocomposites as well as requirements on the calibration for this type of sensor. Based on the frequency responses, accelerometers and conventional ultrasonic sensors are compared with the new broadband ultrasonic sensor.

Furthermore, the practical use of the sensor concept based on field measurements of rolling bearings is demonstrated. A slow-running rolling bearing is used to describe how damage detection is carried out using the broadband measurement technique. In addition, the extended analysis of the ultrasonic data is described. This makes it possible to use the ultrasonic data to identify the fault pattern and thus the possible cause.

Discover more about the conference