Ultrasonic Clamp-On Flow Meter

SONOFLOW® CO.55 for Non-Contact Contamination-Free Flow Measurement on Flexible Tubes

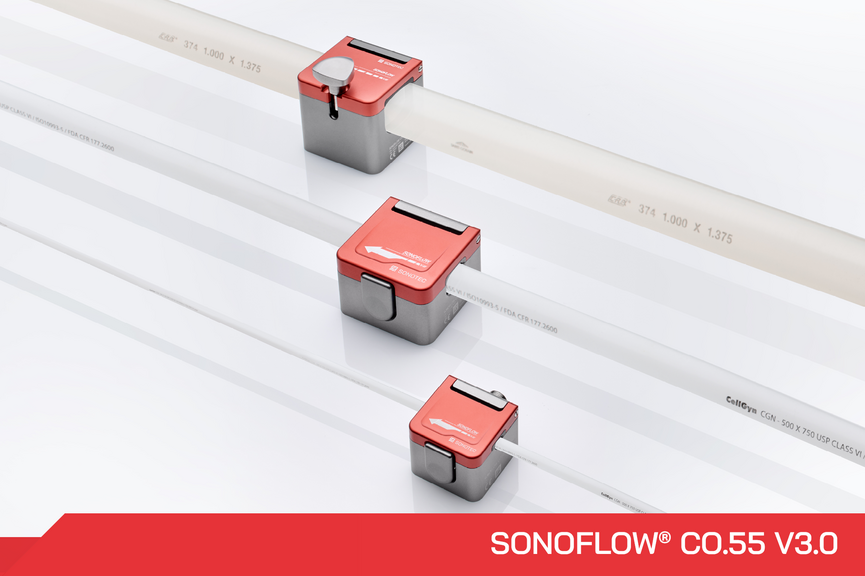

The ultrasonic clamp-on flow meter SONOFLOW CO.55 measures the flow rate of liquids in flexible plastic tubing fast and reliably. The non-invasive sensor made of aluminum or stainless steel does not have any contact to the medium and is particularly suited for applications with strict hygienic standards. The clamp-on mounting concept eliminates any risk of contamination or leakage.

For non-contact measurements on rigid plastic tubes and pipes, the SEMIFLOW CO.65 Ultrasonic Clamp-On Flow Sensor is the perfect solution.

Product Benefits

- Clamp-on ultrasonic flow meter for highly accurate liquid flow measurement - even at low flow rates and dynamic flow rate changes

- Non-contact measurement without any impact on the liquid or cells

- GMP-ready stainless steel housing with color touch display

- Fast measurement of pulsating and bidirectional flow

- Convenient volume dosing feature

- Integrated electronics, no external electronic board required

- Compact housing for smallest footprint

Bioprocessing Applications for Ultrasonic Clamp-On Flow Meter SONOFLOW® CO.55

Upstream Processes

| Media Prep | Replacing scales for volume measurement |

|---|---|

| Inoculation | Injecting cell lines into the reactor |

| Bioreactor | Feeding media / nutrients, control flow into and out of the bioreactor and ATF filters |

| Centrifugation | Determining flow / no flow |

Downstream Processes

| Buffer Prep | Replacing scales for volume measurement |

|---|---|

| Chromatography | Balancing acid / base delivery to the system |

| Filtration | Controlling process conditions during filtration |

| Tangential Flow Filtration | Measuring flow rates on feed, permeate, or retentate lines |

| Fill / Finish | Measuring volume of fluid dispensed into containers |

SONOFLOW® CO.55 Ultrasonic Clamp-On Flow Meter: Application Fields

- Dosing systems

- Bioprocessing

- Pump protection

- Vaccine manufacturing

- Aliquotation

- Lab use

- Mixing equipment

- Chemical supply systems

More Information about Ultrasonic Flow Meters

Do you have any questions?

Feel free to contact us! We will be happy to help you.